Our Self esteem® industry experts will carry out an E&L risk assessment To guage the applicability on the extractable profile knowledge (EU GMP Annex 1) and information you in the overall validation system.

Rinse-sampling was carried out with purified drinking water. The goal was to make certain that the rinse sample is instantly related to the remained concentrate on residue which was described as being the worst situation and rinse method is acceptable to remove the residue from model surfaces validated in Restoration research. Spiking standard was pipetted from inventory Resolution for the product surfaces. Following drying at room temperature, Methanol and h2o (sixty:forty) solvent combine was utilized to rinse the model sheet to a plate and shaking about five min on a shaker. The extract was transferred into a take a look at tube.

In addition, documents evidencing completion and adherence into the predetermined cleaning protocol are a must.

— breakdown goods from the detergents, acids and alkalis Which may be utilized as Element of the cleaning course of action.

The final rinse sample shall be gathered in a means that the sample consultant of the whole rinse volume.

nine.1.1 Equipment must normally be cleaned right away right after use. This may be Specially essential for operations with topical goods, suspensions and bulk drug or the place the drying of residues will right have an affect on the efficiency of the cleaning procedure.

By keeping educated and adopting very best methods, pharmaceutical manufacturers can sustain higher click here expectations of cleanliness, protect patient security, and make sure the quality of their items within more info an at any time-evolving industry.

Chance assessment: A radical possibility evaluation from the procedures for use for cleaning the tools must be performed. A danger-centered approach should be followed when establishing a cleaning validation protocol.

Acceptance conditions in cleaning validation is often categorized into three tests parameters: Bodily, chemical, and microbial conditions.

Proper cleaning methods & analytical processes confirm the efficacy of cleaning methods, like developing sampling places & swab sampling procedures to search for evidence of residue before a producing course of action commences.

— products residue breakdown occasioned by, e.g. the usage of strong acids and alkalis during the cleaning course of action; and

Additionally they spotlight the importance of applying successful cleaning & disinfection methods & validating cleaning strategies to prevent contamination & cross-contamination.

8.three The period and circumstances for storage of unclean tools in advance of cleaning, and some time concerning cleaning and equipment reuse, ought to kind Section of the validation of cleaning techniques.

Collaboration with cleaning solution suppliers: Function intently with cleaning products suppliers to acquire professional guidance, assist, and validated cleaning products and solutions.

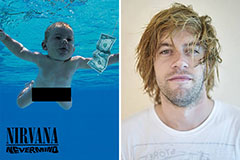

Spencer Elden Then & Now!

Spencer Elden Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!